Mujin is a robotics and automation startup founded in 2011, headquartered in Tokyo, Japan. The company was established by two engineers Issei Takino from Japan and Rosen Diankov from Bulgaria. They aimed to revolutionize industrial automation by integrating advanced AI with robotic systems.

Unlike traditional robots that require explicit programming for each task, Mujin’s technology enables robots to autonomously make decisions and adapt to new situations without human intervention. The company’s core innovation lies in its MujinController, a sophisticated AI platform.

(Source: Mujin Corp)

Mujin has grown rapidly due to its focus on creating intelligent, versatile robotic systems capable of optimizing efficiency, reducing costs, and increasing flexibility in operations. Over the years, it has expanded beyond Japan to global markets, partnering with major corporations to deploy its AI-driven robots in warehouses, factories, and distribution centers.

Mujin’s Core Technology

Mujin, a leader in industrial robotics, has revolutionized the field with its core technology, focusing on intelligent robots and AI controllers. By investing in these technological advancements, Mujin has positioned itself as a leader in the field of robotics. Their innovative solutions have the potential to transform industries and drive economic growth.

Intelligent Robots

Mujin’s intelligent robots are equipped with advanced capabilities that set them apart from conventional industrial robots. These robots are not limited to repetitive tasks but can think and move autonomously. Some key features include:

(Source: Mujin Corp)

-

Autonomous Learning

Unlike traditional robots that require manual teaching, Mujin’s robots can learn autonomously. They observe their environment in real-time and make decisions based on these observations, allowing them to handle outliers and exceptions without manual intervention.

-

High-Speed Analytical Inverse Kinematics

Mujin’s Kinematics Calculation Library enables robots to solve inverse kinematics equations swiftly and optimally, enhancing the efficiency of industrial processes.

-

Motion Planning with Real-World Considerations

Mujin’s robots can record their trajectories while being moved manually, eliminating the need for extensive programming. This adaptability allows them to navigate complex environments seamlessly.

-

3D Recognition Technology

The intelligent vision algorithm mimics human situational assessment, enabling robots to identify objects and make informed judgments based on the surrounding context. Mujin’s robots are equipped with high-resolution cameras and advanced vision algorithms that allow them to accurately perceive their environment and identify objects.

AI Controllers

(Source: Mujin Corp)

(Source: Mujin Corp)

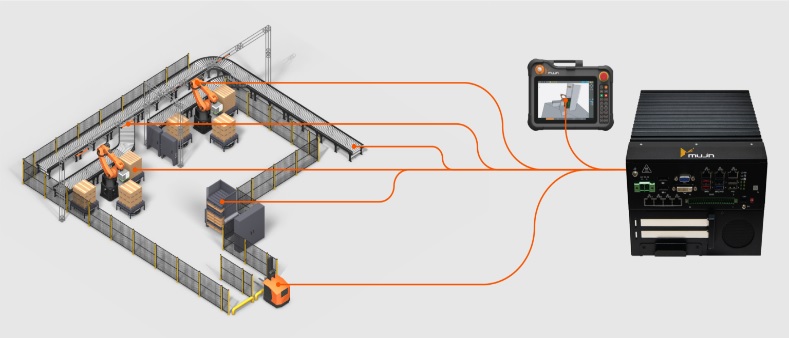

At the heart of Mujin’s technology is the MujinController, a universal platform that transforms industrial robots from any manufacturer into intelligent machines. The MujinController offers several advantages:

-

Seamless Integration

The platform allows for the deployment of industrial robotics systems without the need for complex advance settings and integration, including motion settings and peripheral equipment.

-

Real-Time Decision Making

MujinController enables robots to make effective decisions in real-time, ensuring they can adapt to changing conditions and perform tasks with precision.

-

Enhanced Productivity

By automating various applications across manufacturing and logistics, the MujinController significantly boosts productivity and quality, helping companies achieve higher efficiency.

Human-Robot Collaboration

Mujin is committed to developing robots that can safely and effectively collaborate with human workers. This involves designing robots that are intuitive to interact with and that can understand and respond to human cues. Mujin’s collaborative robots are designed to work alongside humans, sharing tasks and responsibilities. They are equipped with safety features to prevent accidents and ensure the well-being of human workers.

Artificial Intelligence and Machine Learning

One of Mujin’s key areas of focus has been the integration of artificial intelligence (AI) and machine learning (ML) into their robotic systems. By leveraging these technologies, Mujin has been able to develop robots that are more intelligent, adaptable, and capable of learning from experience.

-

Deep Learning for Object Recognition

Mujin’s robots utilize deep learning algorithms to accurately identify and classify objects in complex environments, even when they are partially obscured or cluttered.

-

Reinforcement Learning for Task Optimization

Reinforcement learning techniques enable Mujin’s robots to learn from their interactions with the environment and optimize their performance over time. This allows them to adapt to changing conditions and improve their efficiency.

Benefits of Using Mujin

Mujin’s advanced AI-powered systems offer numerous benefits across various industries. By integrating cutting-edge technology into traditional automation processes, Mujin significantly enhances operational efficiency. Below are the key benefits of using Mujin’s systems in industrial settings:

1. Increased Operational Efficiency

Mujin’s technology enables robots to operate autonomously, without the need for manual programming or constant supervision. By automating these processes, businesses can maintain higher levels of productivity while minimizing errors and reducing reliance on human labor.

2. Continuous Operation

Robots equipped with the MujinController can work 24/7, boosting throughput and ensuring faster processing times.

3. Real-Time Motion Planning

Mujin robots optimize their movements in real time, reducing idle time and improving the overall speed of operations.

4. Reduced Labor Costs

Robots can take over tasks that traditionally require large numbers of manual workers, particularly in sectors like warehousing, logistics, and manufacturing. This not only cuts costs related to wages but also lowers expenses associated with training, supervision, and turnover.

5. Flexibility and Adaptability

Traditional automation systems are limited in their ability to handle product variability and environmental changes, requiring manual reprogramming for new tasks. Mujin’s AI-powered robots, however, can adapt to changing conditions, product types, and workflows on the fly.

6. Improved Accuracy and Precision

Mujin’s systems are equipped with advanced machine vision technology that allows robots to interpret their environment in real time, leading to higher precision in tasks. By improving accuracy, Mujin’s robots reduce the risk of errors, product damage, or defects, leading to better overall product quality and lower waste.

7. Reduced Downtime

Mujin’s systems minimize downtime by enabling robots to autonomously adjust to new tasks, products, and workflows without requiring manual reprogramming. This allows businesses to remain agile and responsive to changing demands, such as seasonal fluctuations, without interrupting production.

8. Enhanced Safety for Workers

Mujin-powered robots reduce the need for humans to perform hazardous, repetitive, or physically demanding tasks, enhancing workplace safety. In environments like manufacturing plants or warehouses, where tasks such as heavy lifting, palletizing, or working with sharp objects are common, robots can perform these jobs without risk to human health or safety.

9. Scalability for Growing Operations

Mujin’s systems are highly scalable, making them ideal for businesses that expect growth or fluctuating demand. The flexibility of the MujinController allows companies to easily expand their automation processes without having to overhaul their entire infrastructure or invest in new equipment.

10. Global Competitiveness

By adopting advanced automation solutions like Mujin’s, businesses can remain competitive in an increasingly automated global market. Faster production times, higher efficiency, and lower costs allow companies to keep pace with international competitors and meet growing customer expectations for quick delivery and high product quality.

Applications of the MujinController

(Source: Mujin Corp)

The MujinController has become an essential tool across a wide range of industries due to its flexibility, AI-powered intelligence, and real-time motion planning capabilities. By enabling robots to operate autonomously in dynamic environments, the MujinController has become an essential tool in increasing efficiency, reducing costs, and boosting productivity. Below are some of the key applications of the MujinController:

1. Warehouse Automation and Logistics

One of the most prominent applications of the MujinController is in warehouse automation. Modern logistics and e-commerce industries require fast, efficient handling of products to meet increasing consumer demands. The MujinController powers robots used for critical warehouse tasks, such as picking, sorting, and packing.

-

Picking and Sorting

Robots equipped with MujinControllers are capable of picking items of varying shapes, sizes, and weights from shelves or bins. The machine vision integrated with the MujinController allows the robots to “see” and identify objects, making real-time decisions on how to pick and handle items.

-

Packing

In automated packing lines, Mujin-powered robots can handle the complexities of packaging diverse products efficiently. The AI allows the robots to adjust to different product sizes, ensuring optimal packing density while reducing errors.

-

Palletizing

The MujinController’s ability to plan real-time motion helps robots create optimized pallet layouts. Whether stacking or unstacking, Mujin-powered robots can autonomously determine the best strategy based on the size and shape of packages, improving warehouse throughput and reducing human labor costs.

2. Manufacturing and Assembly Lines

In the manufacturing sector, where precision, speed, and adaptability are critical, the MujinController plays a vital role in improving operational efficiency. Robots using the controller are deployed in various tasks such as assembly, material handling, quality inspection, and welding.

-

Assembly Lines

The MujinController automated robots to assemble complex products by intelligently adjusting to different components, making them ideal for industries like automotive and electronics manufacturing. The flexibility of the controller allows the same robot to handle multiple assembly processes, reducing downtime.

-

Material Handling

In environments where raw materials need to be moved frequently, Mujin-powered robots excel at loading and unloading items. The controller ensures smooth motion planning, making sure the robots operate efficiently even in crowded or dynamic workspaces.

-

Quality Control and Inspection

Robots with MujinControllers can use integrated vision systems to perform quality checks on finished products. The AI controller analyzes whether products meet the required specifications and autonomously identifies defects, reducing the need for human inspectors.

3. Robotic Bin Picking

One of the most challenging tasks in industrial robotics is bin picking, the act of retrieving specific items from a mixed or unstructured bin. The MujinController’s machine vision and AI capabilities make this possible with a high degree of accuracy. Robots using the controller can recognize and pick random objects from a bin without pre-programmed paths. This is particularly useful in logistics, pharmaceuticals, and retail warehouses, where product sizes and orientations vary significantly.

4. Automated Material Transportation

The MujinController also powers autonomous material transportation robots, which are used in factory floors and distribution centers. These robots can move raw materials, semi-finished products, or finished goods from one place to another, using real-time data and sensors to avoid obstacles and determine optimal paths. This reduces bottlenecks and ensures smooth transitions between different production or logistical stages.

5. Robotic Welding

The MujinController’s real-time motion planning and precision are also leveraged in robotic welding. In the automotive and heavy machinery sectors, Mujin-powered robots can autonomously weld complex structures with high precision. The controller dynamically adjusts the robot’s motion and welding parameters to suit different materials and geometries, reducing human intervention and improving production quality.

6. Depalletizing and Sorting in Distribution Centers

In distribution centers, where goods arrive on pallets and must be unpacked, sorted, and stored, Mujin-powered robots excel at depalletizing. Robots using the MujinController can scan pallets, determine the best method for removing items, and sort them efficiently. These robots are also used to reassemble pallets based on the destination or order requirements, speeding up operations and reducing labor costs.

7. Collaboration with Autonomous Mobile Robots (AMRs)

MujinController can integrate with Autonomous Mobile Robots (AMRs) to further enhance automation. While Mujin-powered robots handle tasks such as picking and packing, AMRs transport goods between different areas of a facility. This combined effort creates an entirely automated workflow, where goods move seamlessly from one stage of production or storage to another, with minimal human intervention.

8. AI-Powered 3D Scanning and Inspection

In industries like aerospace and automotive manufacturing, ensuring that every part meets stringent quality standards is essential. The MujinController’s machine vision technology enables robots to perform detailed 3D scanning of parts and products. This automated inspection process identifies defects or irregularities with precision, reducing the chances of faulty products reaching the end customer.

9. Food and Beverage Industry

The MujinController is also finding applications in the food and beverage industry, where robots handle tasks like sorting produce, packaging food items, and organizing products for distribution. With the controller’s ability to work in dynamic environments and its machine vision capabilities, robots can sort and handle perishable goods efficiently, ensuring quality and freshness are maintained.